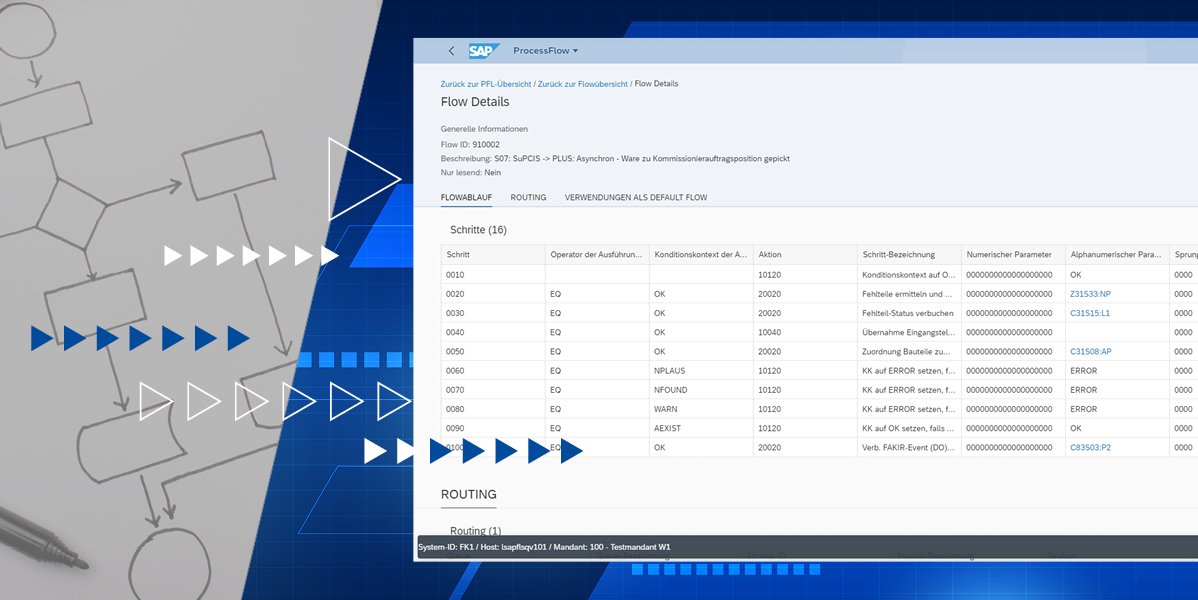

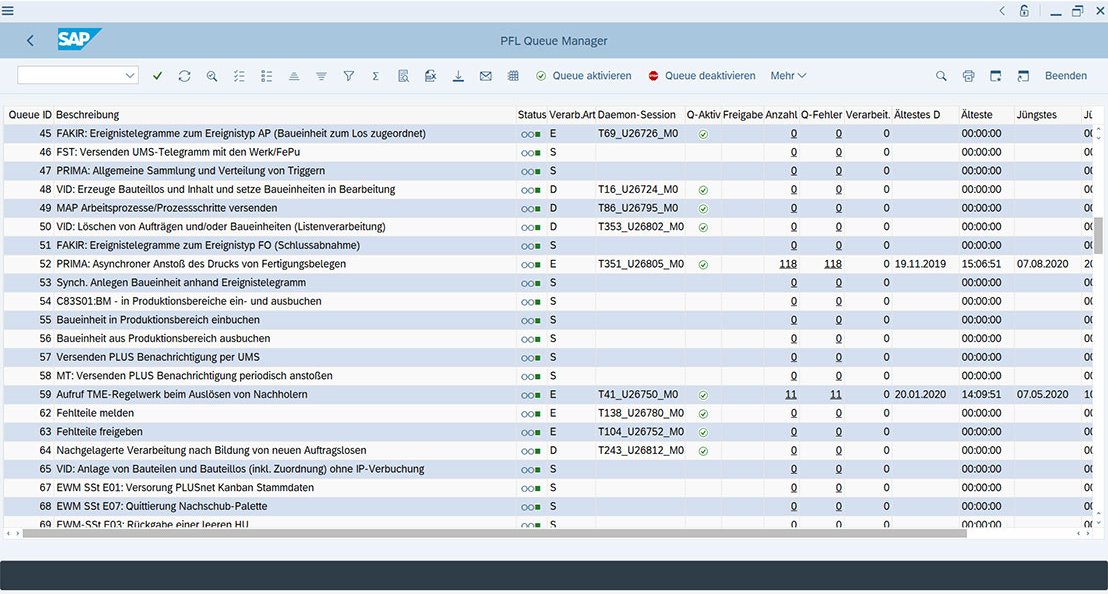

Our intelligent MES platform enables the clean separation of transactional data (orders and their characteristics) and operational data in a separate, lean data model. In addition, lot management is provided to manage, display and process lot sizes >1.

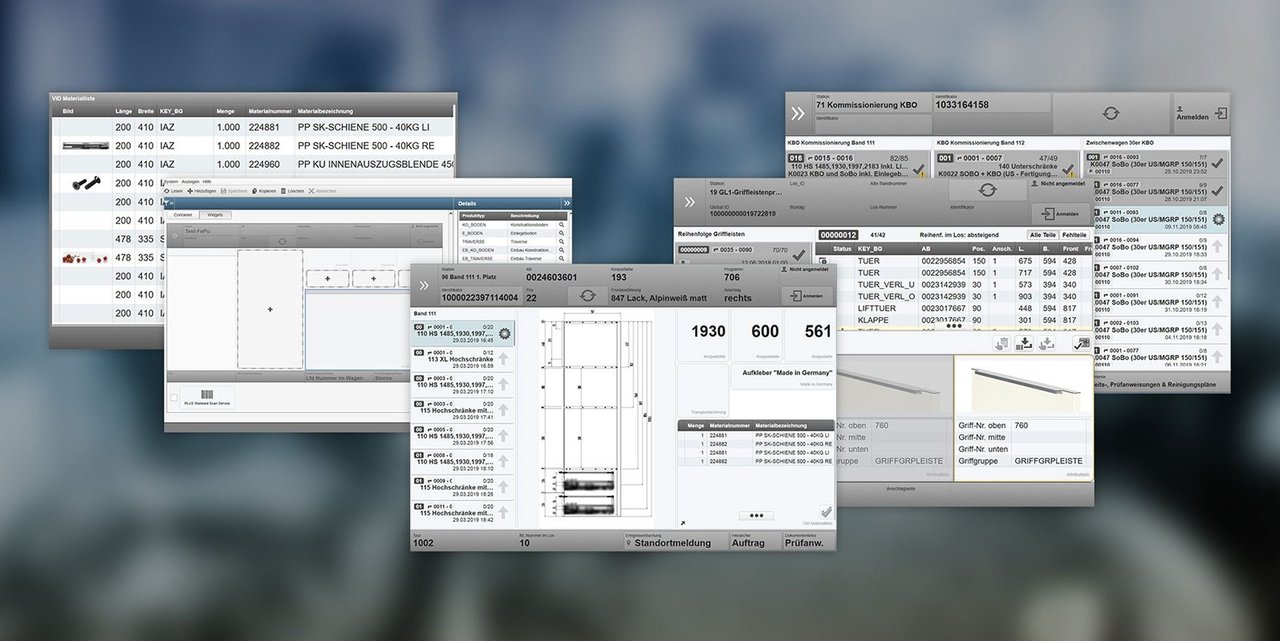

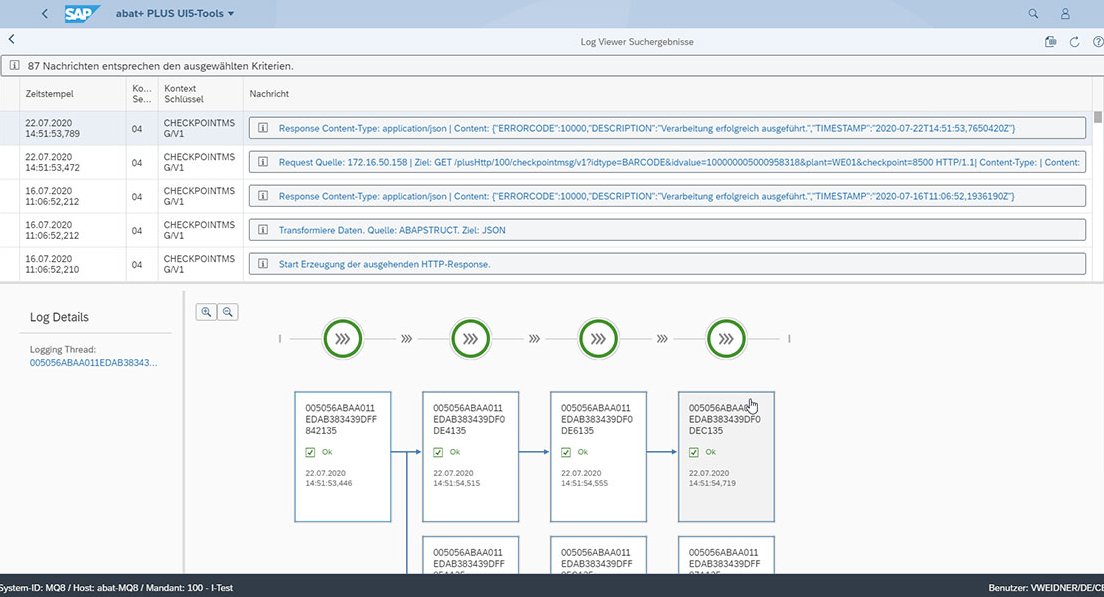

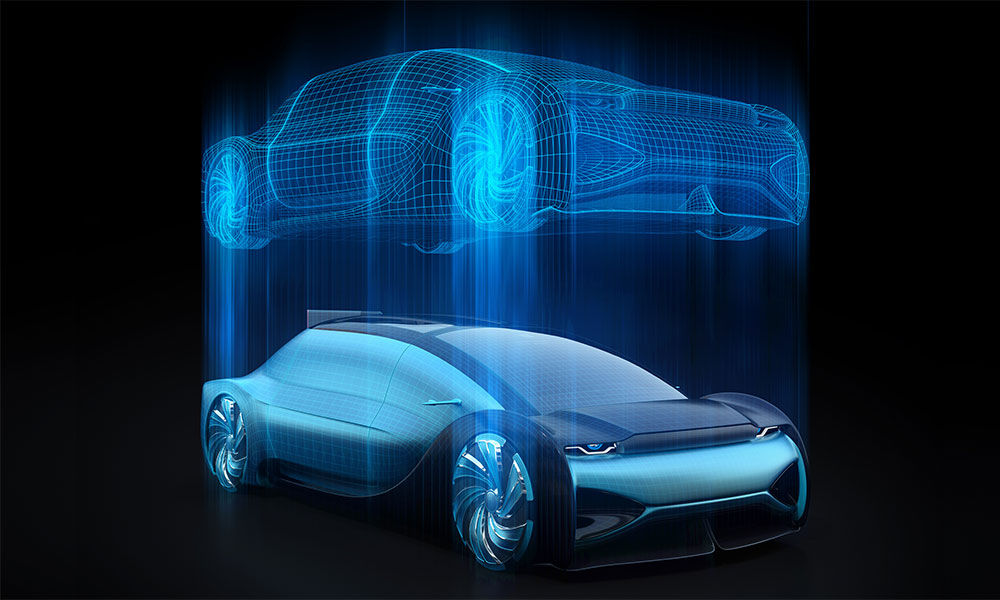

Production data is captured on the "digital twins" of the orders or lots, which represent the existing physical objects within the production. This allows the physical world to be visualized and monitored for lot sizes 1 to n as a real-time digital image of production. In addition, comparisons of the actual world to the target specifications can be easily made.